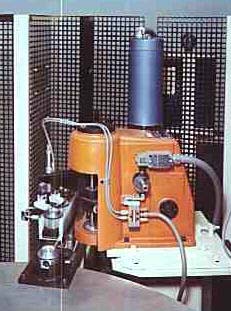

Automatic dial index machine produces piston subassemblies

Newcor Bay City Division (Bay City, MI) has designed, engineered, and produced a fully automatic piston subassembly machine to provide pistons for an A/C compressor motor. The machine uses a dial index table with six assembly stations. As each state adds a component to the piston, the assembly is rotated and advanced to the next station/operation in the sequence until a completed piston subassembly is finished. The finished piston subassembly is automatically unloaded to an accumulating conveyor where an operator offloads it.

Components to the pistons are automatically fed through part feeders or magazines. Once the piston has a component added atone of the stations, a part detector is used to assure that the assembly has been properly built prior to advancing to the next station. If the components are not present or properly added to the subassembly, the station signals a "no operation" to an operator.

The machine was designed to operate only when piston subassemblies are needed. When the accumulating conveyor for the completed assembly is depleted to a specific level, the piston subassembly machine automatically replenishes the conveyor.

Assembly machines, used to add the piston components, incorporate both DC motor driven, cam-type pick-and-place units and DC motor-driven inline slides.

Designed operating speed of the machine is in excess of 400 parts per hour; though the maximum speed required in this application was only 160 parts per hour.

Newcor Bay City Div. of Newcor, Inc. is a leading producer of assembly, welding, forming, heat-treating, testing and fully integrated manufacturing systems.

Newcor Bay City Division, 1846 Trumbull Drive, Bay City, MI 48707-0918 USA; phone: 517-893-9505