Delcam reworks high-speed machining fundamentals

Delcam's PowerMILL machining software has long been regarded as the leading system for the generation of NC programs for high-speed machining. As Delcam's experience of high-speed machining has grown, it has become increasingly apparent that companies introducing this technology cannot rely solely on a faster spindle speed to give the results they want. Work undertaken in conjunction with cutting tool consultants H.R. Pearce and Mitsubishi Carbide has shown that a major change is needed in the fundamentals of the whole machining process before users can gain the full benefits of any investment in high-speed equipment.

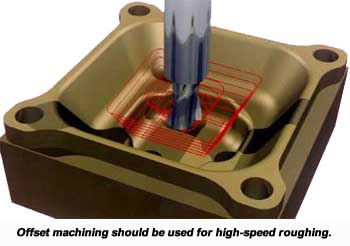

The main requirements of the machining strategies are to keep the load on the cutter as consistent as possible, and so maximize the life of the cutter, and to minimize any sudden changes in the cutting direction that will necessitate a slowing in the cutting operation. One of the basic changes in strategy needed to achieve these conditions is the use of offset machining for roughing rather than the traditional raster approach. Whenever possible, machining should be completed from the center of the job outwards to minimize any need for full-width cuts.

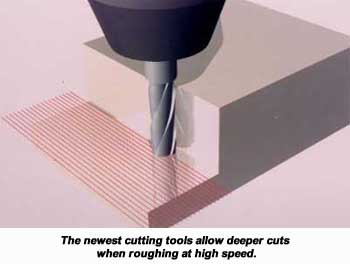

The initial advice for high-speed machining was to keep both the step-over and step-down small compared to conventional machining. Recent developments in cutting tool technology mean that the latter restriction no longer applies.

Roughing with deeper cuts is now possible by using a ball-nose cutter with four or six flutes that can cut with the side of the tool. The step-over, however, must still be comparatively small. Cutting with the side of the tool can also be used to optimize finishing routines by working from the bottom upwards when finish machining steep walls.

Climb machining is recommended for all roughing operations, as this will reduce tool wear. Although this approach does involve extra air moves, this time can be made up by maximizing the speed of the cutting moves. A combination of conventional and climb machining can be used safely in finishing operations where less than 0.3 mm of material is being removed.

With both rough and finish machining, arcing moves should be used when approaching and leaving the job. Plunging onto the surface of the part should be avoided as this slows down the cutter and leaves a dwell mark on the surface.

When cutting corners, the radius of the cutter needs to be considerably less than the radius of the corner, so that the maximum contact distance can be kept to less than 30% of the circumference of the cutter. This allows sufficient cooling to take place and also avoids a sharp increase in the load on the tool as it enters the corner.

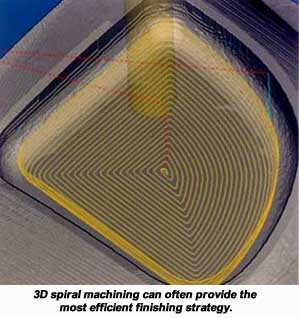

For many shapes, finish machining can be carried out most effectively with a 3D spiral strategy. This avoids the frequent changes in direction that can occur with both raster and offset finishing strategies, and so allows faster machining and reduces the wear on the cutters.

Support for all these strategies is, of course, available within PowerMILL, as part of Delcam's commitment to provide the complete machining solution for both toolmaking and production machining.

Support for all these strategies is, of course, available within PowerMILL, as part of Delcam's commitment to provide the complete machining solution for both toolmaking and production machining.

Delcam plc, Small Heath Business Park, Birmingham, B10 0HJ UK. Tel: +44(0)121 7665544. Fax: +44(0)121 7665511.

Delcam International, Inc., 3270 Electricity Drive, Windsor, ON N8W 5J1 Canada. Tel: 519-974-8088. Fax: 519-974-8170.

Source: Delcam