EdgeCAM 5.5 builds on success in complex machining

Pathtrace's newest release advances functionality.

EdgeCAM 5.5, the new release from Pathtrace Systems, Inc., incorporates a wide range of new technology and productivity-enhancing features for both production and mold and die machining. In fact, Brian Steatham, Chairman of the Pathtrace Group told Machine Tools Online, "We give equal importance to both prismatic machining and mold and die work."

EdgeCAM 5.5 builds on the success of Version 5.0, which established its reputation for ease of use and its wide range of productivity tools, said Steatham.

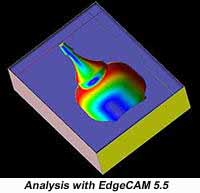

For mold and die machining, EdgeCAM 5.0 introduced a suite of surface machining features collectively known as Secure Surface Machining Technology to meet market demand for advanced surface machining capabilities. Version 5.0 employed superior surface machining algorithms for improved performance and reliability, greater accuracy, and gouge-free machining.

For mold and die machining, EdgeCAM 5.0 introduced a suite of surface machining features collectively known as Secure Surface Machining Technology to meet market demand for advanced surface machining capabilities. Version 5.0 employed superior surface machining algorithms for improved performance and reliability, greater accuracy, and gouge-free machining.

EdgeCAM 5.5 takes this advanced functionality to another-higher level. Enhancements include added functionality and features in both Secure Surface Machining and in production/prismatic machining.

Mold & die machining advances

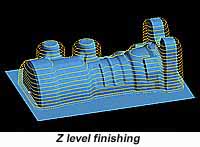

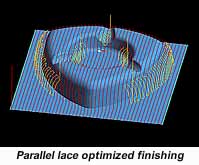

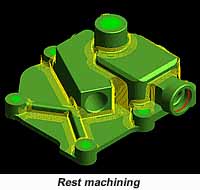

Additional Secure Surface Machining functionality includes rest finishing, multi-tool rest roughing, finishing of shallow areas in Z level finishing cycle, and toolholder collision detection, among others.

Additional Secure Surface Machining functionality includes rest finishing, multi-tool rest roughing, finishing of shallow areas in Z level finishing cycle, and toolholder collision detection, among others.

- Rest finishing automatically detects all areas that cannot be machined by a large tool and produces a constant cusp toolpath with a smaller tool. This allows larger tools to be used for machining the majority of the part, which can significantly reduce the total cost of machining time.

- Multi-tool rest roughing automatically detects all areas that have not been cleared by the previous roughing toolpath and machines them with a smaller tool.

- Z level finishing on its own will not produce a good surface finish on shallow areas, but a new finish shallow option allows these to be automatically detected and machined using a constant cusp toolpath.

- Tool holder collision checking considers tool holder profile against the model, and special allowances can be created to distance the tools from the clamps.

Advancing production machining

Major improvements to the prismatic capability in EdgeCAM include many enhancements to drilling and multi-plane machining. These improvements offer major time-savings in both programming and machine tool cycle time.

- Optimized drilling: intelligent processing of geometry Intelli-Drill (Depth tab) allows parameters such as level, depth and diameter to be determined from the digitized geometry. Any drilling cycle may now include holes with differing levels and depths.

- Optimizing drilling toolpaths include shortest distance as well as x lace, y lace and nearest partners.

- Rationalize sequence allows the user to program in a feature-based manner but deliver NC code optimized for the Machine Tool. After the machining in a feature-based manner has been completed, the user can then rationalize the sequence around Tool Usage or Index Position, thus reducing the CNC time on the machine.

- Island facing allows flat islands to be machined during an area clearance or lace cycle. An additional Z offset to specify an amount of material to be left on top of the island can also be specified.

- ToolStore: job manager reports are intranet-based reports that allow all information stored with a job to be viewed and printed from any PC with an Internet browser. This removes the need for storing job information on paper that will age and can easily be mislaid. NC programmers, operators, tool setters and production managers are able to access the same critical information whenever they need it. This capability is available to all EdgeCAM users without any extra work on the part of the operator.

Solids machining

EdgeCAM 5.5 has the ability to import files from key major solids modelers. "We don't go through data translation, as other systems do.. We integrate the model and use our own developed feature recognition capability to recognize prismatic features," said Steatham. "In this way we can preserve the integrity of the model without losing data. And it gives us complete associativity. Because there are multiple databases of solid models, we believe that this gives us the most flexibility in meeting the needs of diverse users."

As the solid model is integrated into EdgeCAM, it can be used by the system to collision check the Tool holder against the prismatic toolpaths. A feature normally associated with advanced surface machining CAM systems.

As the solid model is integrated into EdgeCAM, it can be used by the system to collision check the Tool holder against the prismatic toolpaths. A feature normally associated with advanced surface machining CAM systems.

Currently, using EdgeCAM 5.5, machining can be done from most major solid modelers including Inventor, Solid Works, and Solid Edge.

EdgeCAM 5.5 is just now being released and will be available to customers with a current maintenance contract to down load from www.edgecam.com.

Pathtrace Systems, Inc., 3000 Town Center, Suite 830, Southfield, MI 48075 USA. Tel: 248 356-8800. Fax: 248-356-8811.

Pathtrace Engineering Systems, 45 Boulton Road, Reading, Berkshire, RG2 0NH England. Tel: +44 (0) 118 975 6084.

Edited with contribution from Jim Lorincz

Managing Editor

JLorincz@vertical.net