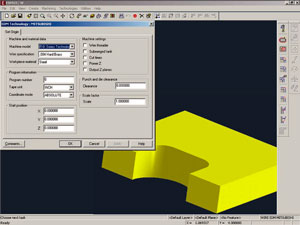

ESPRIT/W 4.0: Wire EDM CAM Software Offers Enhanced Support for Mitsubishi and Brother HS 50-A Machines

CAMARILLO, CA. – DP Technology Corp., a CAD/CAM company today announced the release of ESPRIT/W 4.0, the latest version of the industry's leading CAM software for wire EDM. This version of the software includes all new Knowledge Based Machining (KBM) capability for Mitsubishi wire EDM machines, new support for the Brother HS-50-A machine and updated technology for Agie 123, AgieVision, Charmilles, Charmilles Fanuc, and Ona machine controls.

According to DP's Vice President, Chuck Mathews, "DP's rapid development of new product features, such as those in version 4.0, demonstrates DP's continued commitment to serving the needs of the EDM programmer. This dedication is reflected in ESPRIT's #1 position in the EDM market year after year."

ESPRIT's Mitsubishi Knowledge Based Machining - Now Powered by Microsoft Access Database Technology

Thousands of manufacturers worldwide are using ESPRIT every day to automate the programming of their Mitsubishi wire EDM machines. To automate the process even further, DP has redesigned ESPRIT's Mitsubishi KBM input screens, and added a new Microsoft Access database to store and manage cutting conditions for all Mitsubishi machines. Since the manufacturer also uses this database format, this unique feature offers the significant advantage of database compatibility between the CAM system and the machine tool.

Also, ESPRIT now enables Mitsubishi operators to receive the latest Mitsubishi technology database upgrades directly off the web. Furthermore, operators can edit the manufacturer's factory standard data or even input entirely new data to meet the individual needs of their own shop.

Equipped with this enhanced KBM, the operator need merely specify the work piece material, wire style, material height, and desired surface finish. ESPRIT will do the rest, determining the number of skim cuts per part feature and the underlying cutting methods – such as machine power settings, offsets, feedrates -- required to cut the job. The KBM also allows the operator to choose whether to apply the cut strategy to each individual skim cut or to the workpiece as a whole.

Unique Cutting Strategies for Brother EDMs

DP introduces Knowledge Based Machining for the new Brother HS-50-A wire EDM machine in release 4.0. In cooperation with Brother EDM Machines, DP has designed ESPRIT to optimize cutting times and free the operator for other important tasks. Working together, the software and the machine tool provide new KBM strategies – Roughs First, Per Cavity, Each Cut -- minimizing the operator's time at the machine, while automatically formatting the G-code as advanced conic or 4-axis code as needed. When programmed by ESPRIT, the Brother machine requires almost no operator intervention. Machinists will find these new KBM strategies particularly appealing since they can run the machine at night unattended.

Updated Technology Screens Throughout

In the manufacturing industry, ESPRIT is highly acclaimed for keeping pace with consumer needs. Newly enhanced Knowledge Based Machining technology pages for the Charmilles, ONA, Agie 123 and the AgieVision wire EDM machines continue the trend.

The ONA technology screen now has simplified pages for advanced conics part programming. Some settings have been automated, while others have been combined to make programming choices more clear. Operators will approve of the latest enhancements within ESPRIT's program for the AgieVision Controller as well. The system will easily process even extremely large files by automatically creating sub-programs.

Another significant improvement includes changes to ESPRIT's insert technology pages for the AGIE 123 Controller. Operators are no longer required to manually input NC code line by line to ensure changes in offset register. With a new visual insertion menu, ESPRIT automates this process, allowing the operator to simply "point and click" over a point on the tool path to enter the offset register change.

About ESPRIT and DP Technology Corp.

DP Technology is a company founded on the vision of technology's potential. For two decades DP Technology has set the pace in the machine tool industry with the practical application of advanced technologies for the benefit of the CNC programmer. ESPRIT is packed with 20 years of G-code programming experience, machine tool knowledge, and CNC know-how. ESPRIT reflects a passion for excellence that is fueled by DP Technology's dedication to the needs of the CNC programmer. The company re-invests over 20% of its annual revenue into Research and Development in an effort to assure ESPRIT's continuing leadership as the world's leading CAM product. ESPRIT will be on view at Booth 1338 at the EASTEC show in West Springfield, MA, May 23-25. For additional information about DP Technology and ESPRIT, please call 805-388-6000, email DP at esprit@dptechnology.com or visit them on the World Wide Web at http//:www.dptechnology.com.