Gibbs & Associates to demonstrate GibbsCAM's modules at PMTS

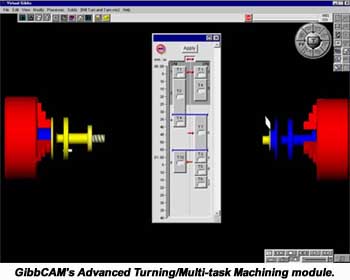

MOORPARK, CA—,Gibbs & Associates developer of Computer-Aided Manufacturing (CAM) software for programming Computer Numerically Controlled (CNC) machinery and controls, today announced it will demonstrate GibbsCAM's Advanced Turning/Multi-task Machining (AT/MTM) and Machine Simulation modules at the Precision Machining Technology Show (PMTS 2001) in Columbus, OH on April 26-29, 2001 at Booth #232 and #234. PMTS is the first event in North America dedicated exclusively to the Screw Machine Industry.

GibbsCAM's Advanced Turning/Multi-Task Machining (ATM/MTM) and Machine Simulation modules address the programming needs of the new breed of CNC multi-task and screw machine tools, which employ multiple tool groups/turrets and multiple spindles. These machine tools are a growing market segment due to their highly efficient operation, which minimizes production costs in set-up and part handling by being able to perform all machining processes required to completely machine a finished part. Reduced inspection, process documentation, and even floor space requirements contribute greatly to an overall reduction in shop overhead. Multi-task machine tools have been somewhat constrained because their overall complexity makes efficiently programming them extremely difficult.

"GibbsCAM AT/MTM significantly extends on GibbsCAM's capability supporting extremely complex multi-task machines, such as multi-turret/spindle lathes with greater than four axes, which go way beyond the capability of what other CAM systems currently offer. AT/MTM supports the enormous variation of MTM CNC machines. Programming these machines has never been easier than with GibbsCAM's drag-and-drop, graphical user interface (GUI)," states Bill Gibbs, company founder and president. "Synchronizing multiple moving elements of a multi-task machine tool and transferring work-in-process pieces are straight forward operations with Multi-Task Machining's Sync Manager." AT/MTM also supports Swiss-style or screw machine turning centers.

GibbsCAM also offers a new Machine Simulation module to provide a machine-level simulation and verification of multi-task machine tool motions. Machine Simulation identifies potential part/tooling/machine interferences in complex programs before being actually run on a machine tool. Errors, which could result in very expensive collisions, can be identified and corrected off-line. Machine Simulation can also be used to identify potential multi-task optimizations.

GibbsCAM also offers a new Machine Simulation module to provide a machine-level simulation and verification of multi-task machine tool motions. Machine Simulation identifies potential part/tooling/machine interferences in complex programs before being actually run on a machine tool. Errors, which could result in very expensive collisions, can be identified and corrected off-line. Machine Simulation can also be used to identify potential multi-task optimizations.

Since 1984, Gibbs and Associates has been a leading developer of CAM software for CNC machining supporting 2- through 5-axis milling, turning, mill/turning, multi-task simultaneous machining and wire-EDM. The current GibbsCAM product line is widely acclaimed for its ease of use and productivity power. The Virtual Gibbs integrated off-line CAM system and the Gibbs SFP embedded shop floor programming CAM system are fully compatible. High-level process models can be bi-directionally exchanged between the shop floor and manufacturing engineering allowing the capture of shop-proven processes for standardization. GibbsCAM also offers fully integrated manufacturing modeling capabilities that include entry-level 2D, 2.5D, 3D wireframe, surface modeling, solid-modeling creation, and the ability to access many CAD data formats. Gibbs and Associates distributes its products worldwide through a network of international Resellers. For more information about Gibbs and Associates and its CAM software packages, call 1-800-654-9399, or visit the company online at www.gibbsCAM.com.

Gibbs & Associates, 323 Science Drive, Moorpark, CA 93021, USA. Tel: 805-523-0004. Fax: 805-523-0006.

Source: Gibbs & Associates