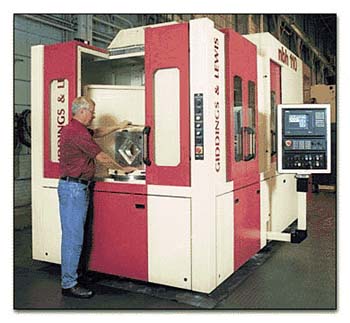

Giddings & Lewis Will Introduce a Big 60-hp HMC

The nbh 170 horizontal machining center will be displayed by Giddings & Lewis Machine Tools (Fond du Lac, WI) in the Crotts & Saunders booth (#1503) at South-Tec 2000. The nbh 170 is a proven German design with more than 150 machines currently in use worldwide.

The 630x500 mm pallet machine has a workspace capable of machining parts 35.4 in. (900 mm) diameter and 43.3 in. (1100 mm) high. The nbh 170 HMC combines speed and power. Its 60-hp spindle drive provides the power for heavy-duty metal removal with traverse rates of 36m/min, a 2.5-sec tool-to-tool change time, and 10-sec pallet change.

A 6000-rpm spindle is standard with higher speed 10,000 rpm and 12,000 rpm spindles available. The cast iron design provides a solid foundation for the machining center's accuracy of ±0.0001 in. (±0.0025mm) positioning and ±0.00004 in. (±0.001 mm) repeatability.

The machine features a 100-tool magazine using two 50-tool cartridges. Additional capacity may be added in 50-tool increments, up to 200 tools. Able to handle large tools needed for heavy machining, the maximum tool weight allowable is 88 lb (40 kg).

The nbh 170 HMC's coolant system includes a self-cleaning, drum-type filter arrangement that automatically backflushes, efficiently removing chips and reducing maintenance normally associated with cartridge-type filters. Capacity of the coolant system is 330 gal (1250 liters).

Crotts & Saunders is the representative for Giddings & Lewis Machine Tools in North Carolina, South Carolina, and Virginia.

Giddings & Lewis Machine Tools, 142 Doty Street, P.O. Box 590, Fond du Lac, WI 54936-0590; phone: 920-921-9400