Innovative HMC delivers a long boring reach for auto industry

Heckert's innovative horizontal machining center is likely to cause a stir in the machine tool industry, especially for automotive applications that require extremely long tooling reaches. In a machine tool world where one horizontal machining center is almost identical to another, Heckert is breaking the mold.

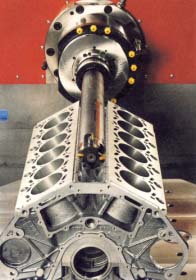

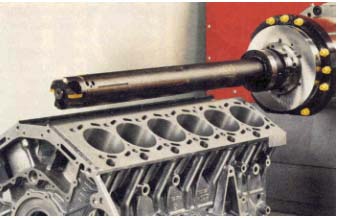

Heckert's highly dynamic horizontal machining center allows tool changing of extremely long tools from a standard tool magazine. This allows the machining center to manufacture large crankcases using in-line boring from one direction, without the need for indexing. The result is a reduction in throughput time of up to 50%, says Dr. Eberhard Schoppe, technical director of Heckert.

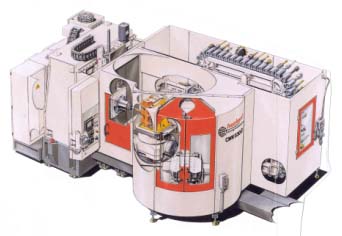

The new high dynamic horizontal machining center, the CWK 630D, is capable of acceleration of 1g (33 feet /s²) and feedrates up to 100 m/min (3,937 ipm). It has the ability to change boring bars and tools up to a length of 31.5" (800 mm) from a standard chain or tower type tool magazine.

Heckert's customers, who are generally in the automotive and automotive sub-contracting industry, gain an enormous advantage of not only being able to machine crankcases, but also of being capable of in-line boring up to 31.5" from one direction without the need for indexing.

Judging by the initial reaction of the automotive industry, the development is being well received. Not only is the CWK 630D machining center able to perform such a long in-line boring operation, but its very rapid feedrates are reducing cycle times for a typical crankcase application by half.

"We are not that surprised with the remarkable positive reaction from our customers within the automobile industry because, in reality, the machining center was specifically designed with them in mind," explains Dr. Schoppe. The machine is literally being ordered straight off the drawing board, he says.

The machine was designed according to what manufacturing engineers in the automotive industry really wanted, says Dr. Schoppe. "We have designed the CWK 630D machining center from the ground upwards, specifically with the automobile / engine industry in mind. The decisive factor being that we consulted with the automobile / engine industry to find out exactly what is lacking with a horizontal machining center for the components that they manufacture."

In general, the machine has been designed for the manufacture of aluminum engine cylinder blocks, crankcases and cylinder heads, as well as gearboxes and transmission housings associated with larger engines, i.e. 8, 10, and 12-cylinder engines. Magnesium can also be machined as well.

There are a number of design concepts associated with the "ground upwards" design philosophy of the CWK 630D, which clearly give it a leading edge compared with its competitors.

First, a very important aspect, is the absolutely unhindered large movement of chips away from the workpiece and, equally important, the massive and rapid removal of chips away from the machine enclosure. The chips are removed directly and centrally from the bed of the machine to the outside of the enclosure. This can be to the front or back of the machine depending on what is most convenient for the customer.

Secondly, there was a conscious effort to strive for a large working envelope which one would normally only expect to find with larger machining centers, without exceeding the normal size and footprint expected from a 630 mm pallet machining center. The result was the ability to machine large 12 cylinder engine blocks and crankcases without any restrictions and hindrances on a small footprint machining center. With axis travels in X, Y and Z of 1050 mm (41.3 in.), 1000 mm (39.3 in.) and 1160 mm (45.6 in.), respectively, the CWK 630D can handle the majority of cylinder blocks and crankcases associated with the automobile industry.

A third aspect of the "ground upwards" design concept, is that the machine was designed with high dynamics with respect to acceleration and deceleration. Dr. Schoppe comments, "Especially significant with the machining of engine components from light metal is use of many tools in a short amount of machining time. For this reason we really concentrated on high dynamics, rapid feedrates in the linear axes and very quick tool changes. The CWK 630D can achieve rapid feedrates up to 100 m/min (3,937 ipm) and accelerations of 1g (33 feet /s²), which is in the realm of linear drive values. The ‘D' associated in the name CWK 630D naturally stands for "dynamic" and with the high rapid feedrates and quick tool change time, the idle time of the machine is significantly reduced. The idle times are on average 10% to 30% less than competitors."

The high dynamics of the machine are enhanced by the low weight of the moving masses in the spindle head column. Schoppe further explains, "We have configured the spindle head column in such a way that is not only light, but extremely rigid. This allows the handling of heavy and extremely long tools. A key aspect of the CWK 630D lies in the column periphery. Our goal from the tooling side was to handle and store heavy and extremely long tools in a standard chain or tower tool magazine and be able to change them like any standard tool".

"For the complete machining of engine components associated with the larger size engines, a boring bar tool of length up to 800 mm (31.5 in.) is required. Until now it was not possible to change a tool that long with an automatic tool change from a standard tool magazine," Dr. Schoppe explains.

Up to now normal procedure has been to use a standard length boring bar and bore from both sides by indexing the components. This, however, is time-consuming and owing to the high accuracy of the operation, is not the optimum solution. Alternatively, a "special" machine is used for this particular operation. It is now possible, and this is the deciding advantage, to offer a machining center that eliminates the need for indexing or using a "special" machine.

The CWK 630D can also automatically change mills of 250-mm (9.84 in.) diameter, with a weight of up to 35 kg (77 lb), directly from the standard tool magazine. It is also no longer necessary to store unconventional tools needed for long in-line boring within the confines of the machining envelope.

This brings obvious advantages, namely, not using up valuable work envelope space for storing the tool and not exposing the tool to the machining environment. Storing the tool in the tool magazine ensures that the tool is protected which, in turn, means greater precision for the components and the life of the tool.

The CWK 630D offers other variables on the tooling side, from the basic 60-tool chain-type magazine through to the 120, 180 and 240 tool tower-type magazine. The customer can also decide between V-flange and HSK tapers.

For both of these tapers there are technical or economic reasons for the selection. Both can be applied at 10,000 rpm, but at 15,000 rpm arguments point to the preferred use of HSK. With the optional 15,000-rpm spindle it is probably necessary to use the HSK 100 taper.

However, Schoppe states, "Many customers are unable to work within the tight tolerances which are required throughout industry nowadays. Today they are searching for ever greater accuracies."

For this reason Heckert offers an optional "accuracy package" with a whole range of opportunities to improve accuracy. The most simple is the warm-up program, which runs the machine before the first chip is cut. It brings the spindle and machine to the correct working temperature. The axis error is further reduced using an axis compensation routine in the CNC as well as a higher caliber counterweight balance on the vertical y-axis.

Furthermore, the accuracy package includes increased accuracy of the mechanical parts of the machine to achieve the very best results.

Schoppe explains, "The manufacturing tolerances are tightened which means that parts of the machine need to be scraped. That means extra cost in time and money—it also improves the machine in terms of positioning accuracy as well as halving the backlash. For the company that needs this improvement, this feature is invaluable."

"A choice of specially made spindles is available for aluminum light metal machining. As standard there is the 10,000 rpm and as an option, 15,000 rpm. The 31 kW (41.5hp) and 200 Nm (145 ft-lb) spindle gives excellent cutting capacity in aluminum, though these values do not impress the cast iron and steel cutting manufacturers because they are not ideal for them. For these manufacturers, we have a different version of the machine, with power and torque curves ideally suited to these materials," says Dr. Schoppe.

Heckert Werkzeugmachinen GmbH, Otto-Schermerbach Strasse 15/17, Chemnitz, 09117, Germany; phone: 0371 866 2300

Starrag-Heckert, Inc., 26071 Merit Circle, Suite 112, Laguna Hills, CA 92653 USA; phone: 949-582-5370