Westec2000: Vericut 5.0 Simulates the Entire CNC Machine Tool and Process

Irvine, CA-based CGTech will demonstrate its Vericut v. 5.0 verification technology in Booth 2529. Vericut software enables users to virtually eliminate the process of manually proving-out NC programs by emulating the material removal process on a computer. The program uses G-codes and CAM output to simulate milling, drilling, turning, wire EDM, and mill/turn machining operations. Operators can correct errors and remove inefficient motion before sending part programs to the shop.

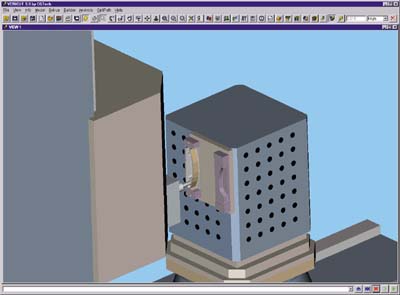

Vericut v. 5.0 features new technology that enables users to simulate entire CNC machine tools and the complete machining process—integrated with material removal. Version 5.0 unifies traditional tool-and-part verification and machine tool simulation. Users can choose to view just the cutting tool and workpiece, or the complete machining environment, including the machine tool and fixtures. The views and orientation can be changed at any time during the machining model.

Vericut v. 5.0 is capable of producing a usable CAD model that accurately represents the in-process material and machined features at each stage of machining. The new version exports IGES data, native CAD formats, and STL. Manufacturers can use this "as machined" model for detailed analysis of machining processes and to check subsequent machining operations. The CAD model export is also a valuable tool for reverse engineering. By accurately representing the workpiece shape, users can create true solid models from NC data.

In addition to machine tool simulation with material removal, v. 5.0 supports the ability to fully manipulate the size, orientation, and positions (zoom/rotate/pan) at any time during the machining process.

The software is designed for multi-threading (working intelligently with multi-processors to enhance performance). Vericut runs under most popular operating systems, including Windows NT/95/98 and UNIX.

N/A, 9000 Research Drive, Irvine, CA 92618; phone: 949-753-1050